Welcome to Taicang Global Machinery Co., Ltd

At Global Machinery, we provide Tube Mill, Roll Forming Machine, Slitting & Cut to length Line and corresponding components, and meet your customized requirements. Contact us right now!

Main Specification

A. Machine technical parameters

1. Machine size: 26m×3m×5m(length×width×height)

2. Feeding direction: right to left

3. Power: 380V, 50Hz, 3P

4. Air source: flux 0.5m3/min; pressure: 0.7MPa

5. Hydraulic oil: 46#

6. Gear oil: 18# hypoid gear oil

7. Coil width: max 735mm

8. Coil thickness: 1.5 – 3.0 mm

9. Coil material:S235JR with yield strength 235Mpa

10. The whole roll forming machine line speed: 5-10 m/min

11. The platform length: 3000 mm

12. Total machine power:about 40KW

B. Product capacity

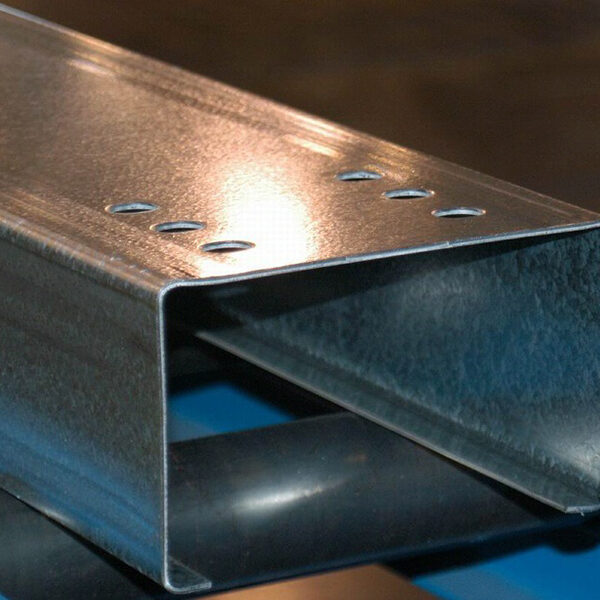

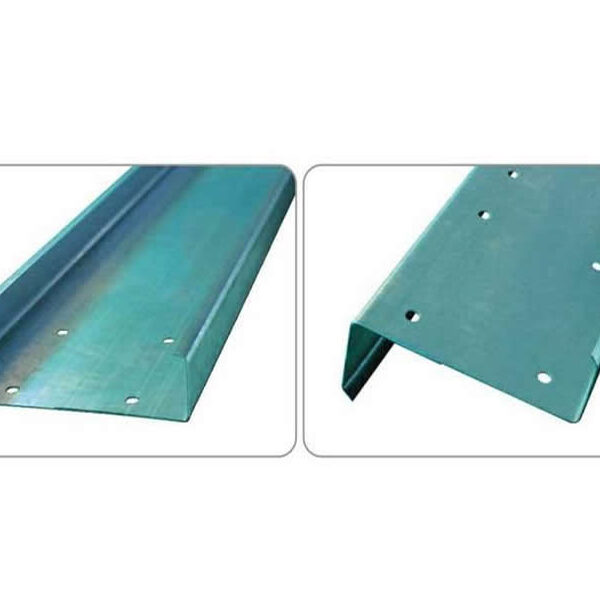

This machine can produce 1.5-3.0 mm platform, the specific drawing as below:

C. Technical flow:

Decoiler → Straightening→ Servo feeding → Punching→ Roll forming→ Cut off →Exit rack

D. Main components technical parameters

1. Decoiler

Coil width:max 735 mm;Coil thickness: 1.5 – 2.5mm;

Coil ID:φ508mm, expansion range: ф480 – 520 mm

With extra 4pcs of 50mm clamp,the expansion range can reach ф580-620 mm

Max coil OD: φ1800mm; Coil weight≤8T

2. Straightening Machine

a. working roll:5 rolls type

b. structure:the straightening roll mechanical properties like rigidity and surface roughness improve a lot after chrome coated and hardening and tempering, which is composed of pinching roll and straightening roll, the pinching roll can be adjusted separately, integral up straightening roll with front-back 2 adjusting points to form certain incline angle, improve the straightening quality.

In the straightening machine feeding section, there are a pair of horizontal guiding roll and 2 pairs vertical guiding roll, vertical guiding roll can be centering and synchronous moved, handwheel adjustment with gauge

In the front and back of straightening machine has lead & guide unit, there is photo-electric signal between straightening machine and feeder, the feedback signal enter control system, the control system send order to converter motor to change speed to control the accumulating volume in accumulating section, thus realize continuous straightening

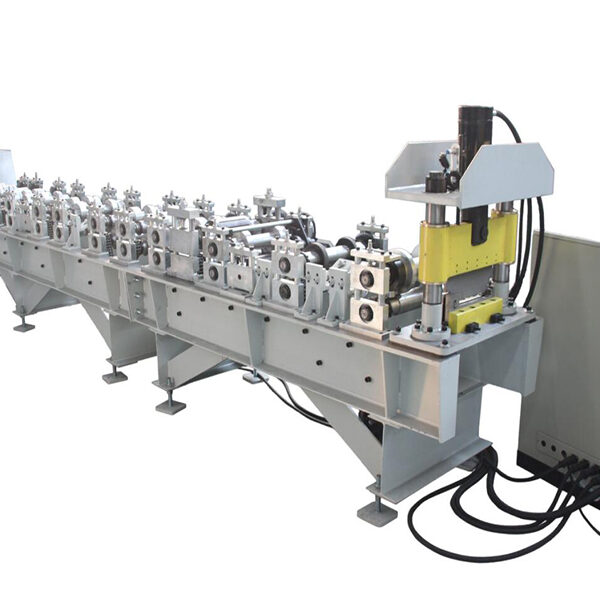

3. Servo Feeding Unit

a. Function: servo feeding

b. Drive: 3kw

c. Feeding distance:set as per production demand

4. Punching Unit

Structure: Yangli Group JF21-160 puncher to punch

Puncher:welded steel plate bed, beautiful and high rigidity

Stamping die: Combined pneumatic core pulling

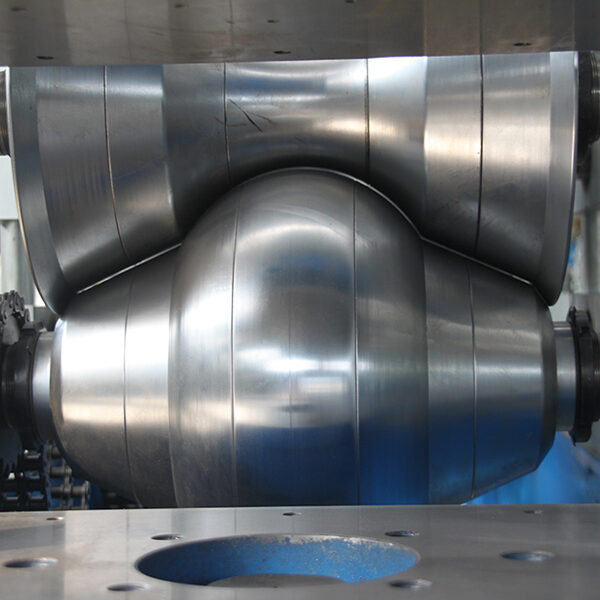

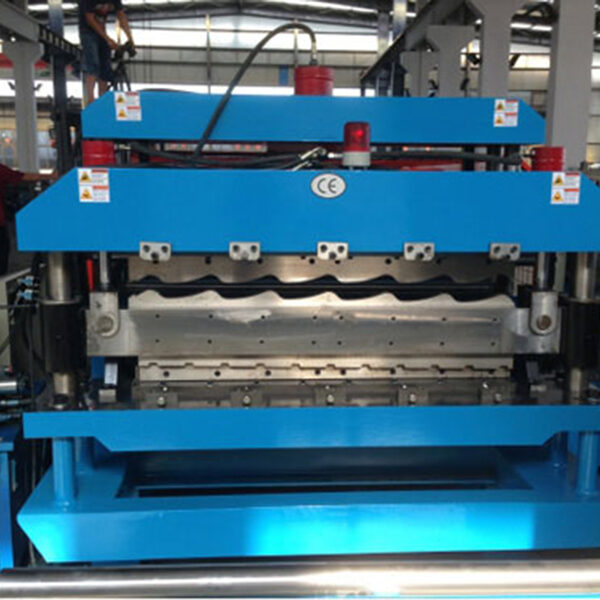

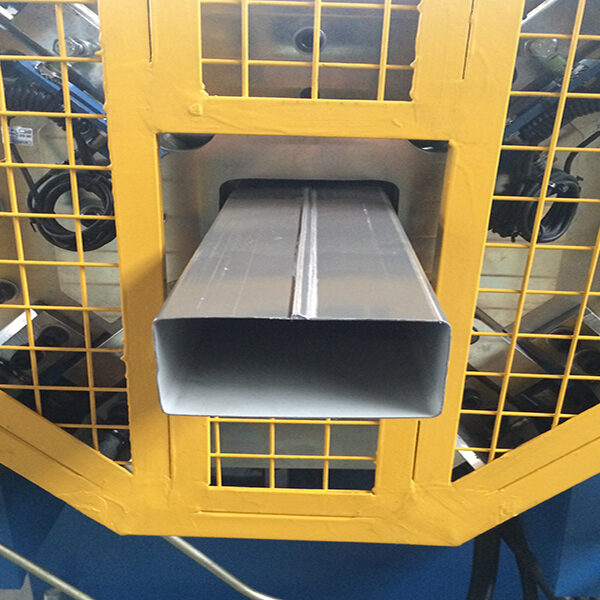

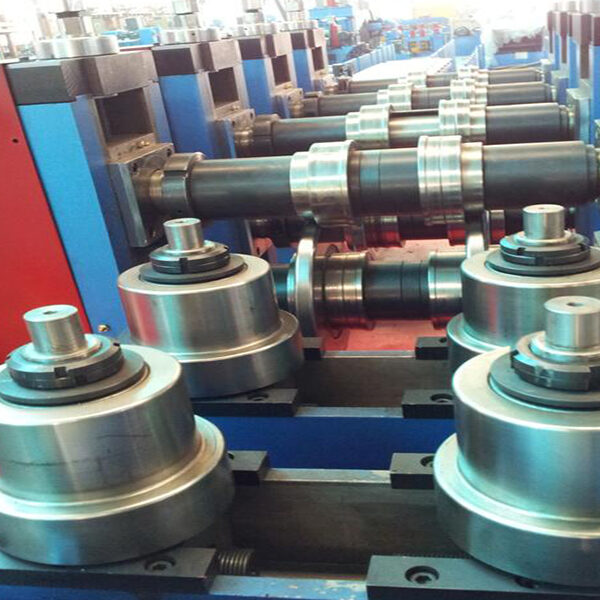

5. Roll Former

Forming station:29 rows

Finished production:scaffold platform

Forming stand: cast iron stand gear box type

Max feeding coil width:900mm

Max coil thickness:1.5-3.0 mm

Roll shaft diameter:φ80 mm

Roll shaft material:Gcr15, quenching, HRC 58-62°

Main drive motor:30kw converter motor

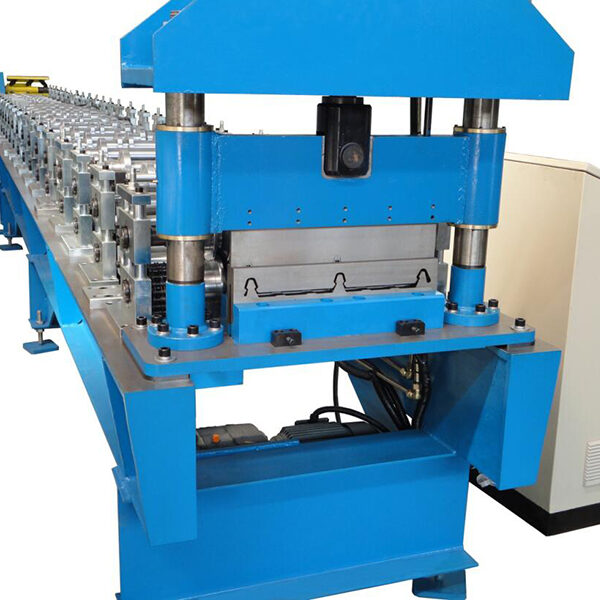

6. Cut Off Unit

a. Type: Hydraulic cut off (with waste material cut off)

b. Structure: locates behind roll former, the cutting length can be set freely.

Blade material: Cr12MoV, no burr with high working life, quick change, very easy and convenient to change blade distance

c. Blade quantity:1 set

7. Exit Rack

Structure: roll type, powerless

E. Electric control system

1. the whole use PLC control, LCD touch screen and HMI, set the program which can run automatically, the operator supervise the control process, realize the operator control the production line and modify the control parameters, and real time monitor the equipment running status, parameters and false alarm, the profile length setting, adjustment etc

2. operation mode has manual and automatic type and freely switch, under manual status, can run a single machine which is convenient for machine maintenance, under automatic status, it conduct the whole line running, start by sequence, the whole line has emergency stop button for emergent matter to secure the machine and personnel safety

3. near the machine has manual operation panel for operator

4 the monitoring function: real time monitoring of production line, monitor each working unit status

Certificate

Main Customers

FAQ

1) Q: Will you deliver the right goods as ordered? How can I trust you?

A: Yes, we will. We are Gold supplier of Made-in-China with SGS assessment (Audit report can be provided). We have cooperated with many customers all over the world with high market reputation, no worries.

2) Q: How to choose the Tube Mill Line?

A: You have to inform us following details:

– The pipe material

– Round pipe range

– Square pipe range

– Rectangle pipe range

– Wall thickness range

– The pipe usage

3) Q: How to choose the Roll Forming Machine?

A: You have to inform us following details:

– Coil material

– Coil thickness

– Coil weight

– Cutting type

– Profiles drawings

– Other special attention

4) Q: How to choose the Slitting Line & Cut to Length line?

A: You have to inform us following details:

– Coil material

– Coil thickness

– Coil width

– Coil weight

– Finished sizes

– Other special attention

55) Q: Where is the nearest airport to your company?

A: Shanghai Putong or Hongqiao Airport.

6) Q: How about your service?

A: Before sales:

– Technical Support: TGMCO will provide detailed technical information such as technical & commercial offer, machine photos, running video, layout, operation manual, and show you working machines in our factory.

– Apply Visa: TGMCO will provide officially invitation letter to apply Visa in china embassy as authority procedures and requirements.

After sales: TGMCO provides comprehensive After Sales Support and Service to meet our customer need.

– Drawings: Provide the foundation drawing, electric scheme and wiring diagram, hydraulic drawing, pneumatic & electric pipeline drawing and other drawings requested by customer.

– Installation and commissioning: TGMCO will send our technicians to customer’s workshop for supervision of installation and commission

Training of Customers’ technician/workers during commission

– Breakdown Support: We offer 1 year warranty service for main crucial components except consumables

Inform immediate technical assistance and advice to customer by phone or e-mail.

Skilled and experienced engineers are capable of dealing with any type of breakdowns.

Technical service work performed in Customer’s site if required.

Urgently supply mechanical or electronic components.

Fast supply of spare parts and wearing parts to cover foreseeable requirements

Packing & Delivery

Not only the Good Machine, but also the Most Attentive Service

Integrity Solution & Turnkey Project

Creat the Value of Steel