Welcome to Taicang Global Machinery Co., Ltd

At Global Machinery, we provide Tube Mill, Roll Forming Machine, Slitting & Cut to length Line and corresponding components, and meet your customized requirements. Contact us right now!

Slited coil is uncoiled and feed into forming section passing through the equipment of entry section. Entry section enables tube mill to run continuously by using strip joining and accumulator. Before welding, pipe is formed in round shape passing through a series of driven and idler rollers of forming section. In welding section pipe is longitudinally welded by using high frequency induction welding method. Outside bead is removed and formed in shape of scrap. The weld seam is ironed and pipe passes through the cooling section. Then in sizing section, pipe is formed to specified size and converted into specified shape. After sizing, pipe is cut to required length by using flying saw cut off equipment and delivered to collecting table after passing through run out conveyor.

Main Specification

| Material | Carbon Steel Cold or Hot rolled Slited coils, galvanized coil |

| Round pipe | 25.4 – 76.4 mm |

| Square pipe | 20 x 20 – 60 x 60 mm |

| Rectangular pipe | 10 x 30 – 80 x 40 mm |

| Thickness square & rec. | 1.0 – 3.0 mm |

| Pipe length | 4.0 – 10.0 meters |

| Line Speed | Max. 90 m/min |

| Welding type | Solid State High Frequency Welding 250kw |

| Model | Round Pipe | Square Pipe | Rectangular Pipe | Thickness | Pipe Length | Line Speed | Welding Type | High Frequency Power/KW | Standard |

| TG16 | 7.5 – 16 mm | / | / | 0. 4 – 1.0 mm | 4.0 – 10.0 meters | Max. 120 m/min | Solid State High Frequency Welding | 60 | / |

| TG20 | 10 – 25.4 mm | 10 x 10 – 20 x 20 mm | 10 x 20 – 10 x 30 mm | 0.4 – 1.0 mm | 4.0 – 10.0 meters | Max. 120 m/min | Solid State High Frequency Welding | 60 | / |

| TG32 | 12.7 – 38.1 mm | 10 x 10 – 30 x 30 mm | 10 x 20 – 40 x 20 mm | 0. 5 – 1.8 mm | 4.0 – 10.0 meters | Max. 120 m/min | Solid State High Frequency Welding | 100 | / |

| TG45 | 15.0 – 50.8 mm | 12 x 12 – 40 x 40 mm | 10 x 20 – 50 x 30 mm | 0.6 – 2.0 mm | 4.0 – 10.0 meters | Max. 100 m/min | Solid State High Frequency Welding | 150 | / |

| TG50 | 20.0 – 63.5 mm | 15 x 15 – 50 x 50 mm | 10 x 20 – 60 x 40 mm | 0.8 – 2.75 mm | 4.0 – 10.0 meters | Max. 100 m/min | Solid State High Frequency Welding | 200 | / |

| TG60 | 25.4 – 76.4 mm | 20 x 20 – 60 x 60 mm | 10 x 30 – 80 x 40 mm | 1.0 – 3.0 mm | 4.0 – 10.0 meters | Max. 90 m/min | Solid State High Frequency Welding | 250 | / |

| TG76 | 31.8 – 89.0 mm | 25 x 25 – 70 x 70 mm | 20 x 30 – 100 x 40 mm | 1.0 – 3.75 mm | 4.0 – 10.0 meters | Max. 80 m/min | Solid State High Frequency Welding | 300 | / |

| TG89 | 38.1 – 102.0 mm | 30 x 30 – 80 x 80 mm | 20 x 40 – 100 x 60 mm | 1.0 – 4.0 mm | 4.0 – 10.0 meters | Max. 80 m/min | Solid State High Frequency Welding | 300 | / |

| TG114 | 38.1 – 114.3 mm | 30 x 30 – 90 x 90 mm | 20 x 40 – 60 x 120 mm | 1.0 – 4.0 mm | 4.0 – 10.0 meters | Max. 70 m/min | Solid State High Frequency Welding | 300 | / |

| TG125 | 63.5 – 127 mm | 50 x 50 – 100 x 100 mm | 60 x 40 – 150 x 50 mm | 2.0 – 5.0 mm | 4.0 – 10.0 meters | Max. 60 m/min | Solid State High Frequency Welding | 400 | / |

| TG165 | 76. 2 – 165 mm | 60 x 60 – 130 x 130 mm | 80 x 40 – 140 x 120 mm | 2.0 – 6.0 mm | 4.0 – 10.0 meters | Max. 60 m/min | Solid State High Frequency Welding | 500 | / |

| TG219 | 89.0 – 219.0 mm | 70 x 70 – 170 x 170 mm | 80 x 60 – 140 x 200 mm | 2.0 – 8.0 mm | 4.0 – 10.0 meters | Max. 60 m/min | Solid State High Frequency Welding | 600 | / |

| API&ERW 168 | 76.2 – 168.0 mm | 60×60 – 130×130 mm | 80×40 – 150×100 mm | 2.0 – 8.5 mm | 5.0 – 12.0 meters | Max 60 m/min | Solid State High Frequency Welding | 600kw | API 5LX, API 5L A&B, ASTM A53 A&B, up to API X-70 |

| API&ERW 219 | 89.0 – 219.0 mm | 70×70 – 170×170 mm | 80×60 – 200×140 mm | 3.0 – 10.0 mm | 5.0 – 12.0 meters | Max 55 m/min | Solid State High Frequency Welding | 800kw | |

| API&ERW 325 | 114.0 – 325.0 mm | 90x90mm – 250×250 mm | 80×100- 200×300 mm | 4.0 – 12.5 mm | 5.0 – 12.0 meters | Max 40 m/min | Solid State High Frequency Welding | 1000kw | |

| API&ERW 508 | 165.0 – 508.0 mm | 130×130 – 400×400 mm | 120×140 – 350×450 mm | 6.0- 12.7 mm | 5.0 – 18.0 meters | Max. 30 m/min | Solid State High Frequency Welding | 1000kw |

Step1: Uncoiler

Uncoiler the function is to support and expand the strip, so strip can enter into machine to roll forming. Strip can be expanded by hydraulic or pneumatic and uncoiler can be rotated 180 degree. Strip expand speed can be adjusted, braking device designed with pneumatic or hydraulic cylinder to press the brake rubber block

Step2: Shear & end welding

It is used to shear the head and the end of the steel strip of two steel coils, cutting off the irregular part then welding two steel strips, so machine can work continuously.

Step3: Accumulator

Installed between shear & end welder and forming mill, horizontal spiral accumulator store a large amount of strip in a reasonable footprint space to give enough time for shear & end welder to cut and join the ends of two successive coils with non-stop tube mill

It has vertical cage type accumulator for small size tube mill

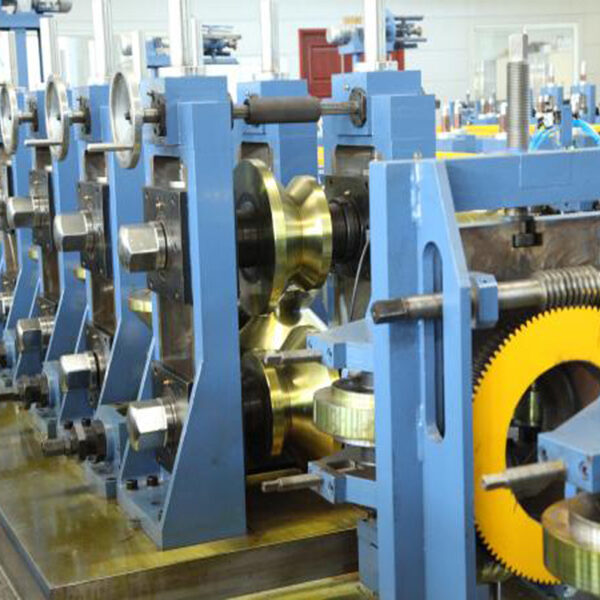

Step4: Forming

The function of this part is to make the steel strip become to the tube blank by forming rollers

Step5: welding & scarfing

The function of this part is to center the welding seam and guide the tube blank to welding device, so the welding seam will be closed before welding, use scarfing tool to remove the burr to ensure the smooth welding

Step6: Sizing

The function of this part is used to finish the tube blank from the forming machine, so the tube size can meet the physical dimension as customer required, form to square and rectangular and other shape profiles

Step7: Straightening

4 rolls turk head straightening, straighten pipe online to achieve the ideal flatness

Step8: Cut off saw

Cut off the pipe with required length, length of pipe can be set

With option of cold saw and flying saw

Step9: Run out table

This unit is to convey the finished pipe to packing, pipe transmit by dynamic roll. A signal sensing device installed in the end of run out table, when pipe touch the signal sensing device, it will feedback the signal to control panel, control panel start working and discharge the pipe

FAQ

1) Q: Will you deliver the right goods as ordered? How can I trust you?

A: Yes, we will. We are Gold supplier of Made-in-China with SGS assessment (Audit report can be provided). We have cooperated with many customers all over the world with high market reputation, no worries.

2) Q: How to choose the Tube Mill Line?

A: You have to inform us following details:

– The pipe material

– Round pipe range

– Square pipe range

– Rectangle pipe range

– Wall thickness range

– The pipe usage

3) Q: How to choose the Roll Forming Machine?

A: You have to inform us following details:

– Coil material

– Coil thickness

– Coil weight

– Cutting type

– Profiles drawings

– Other special attention

4) Q: How to choose the Slitting Line & Cut to Length line?

A: You have to inform us following details:

– Coil material

– Coil thickness

– Coil width

– Coil weight

– Finished sizes

– Other special attention

55) Q: Where is the nearest airport to your company?

A: Shanghai Putong or Hongqiao Airport.

6) Q: How about your service?

A: Before sales:

– Technical Support: TGMCO will provide detailed technical information such as technical & commercial offer, machine photos, running video, layout, operation manual, and show you working machines in our factory.

– Apply Visa: TGMCO will provide officially invitation letter to apply Visa in china embassy as authority procedures and requirements.

After sales: TGMCO provides comprehensive After Sales Support and Service to meet our customer need.

– Drawings: Provide the foundation drawing, electric scheme and wiring diagram, hydraulic drawing, pneumatic & electric pipeline drawing and other drawings requested by customer.

– Installation and commissioning: TGMCO will send our technicians to customer’s workshop for supervision of installation and commission

Training of Customers’ technician/workers during commission

– Breakdown Support: We offer 1 year warranty service for main crucial components except consumables

Inform immediate technical assistance and advice to customer by phone or e-mail.

Skilled and experienced engineers are capable of dealing with any type of breakdowns.

Technical service work performed in Customer’s site if required.

Urgently supply mechanical or electronic components.

Fast supply of spare parts and wearing parts to cover foreseeable requirements

Certificate

Main Customers

Packing & Delivery

Not only the Good Machine, but also the Most Attentive Service

Integrity Solution & Turnkey Project

Creat the Value of Steel